Pneumatic Ingenuity

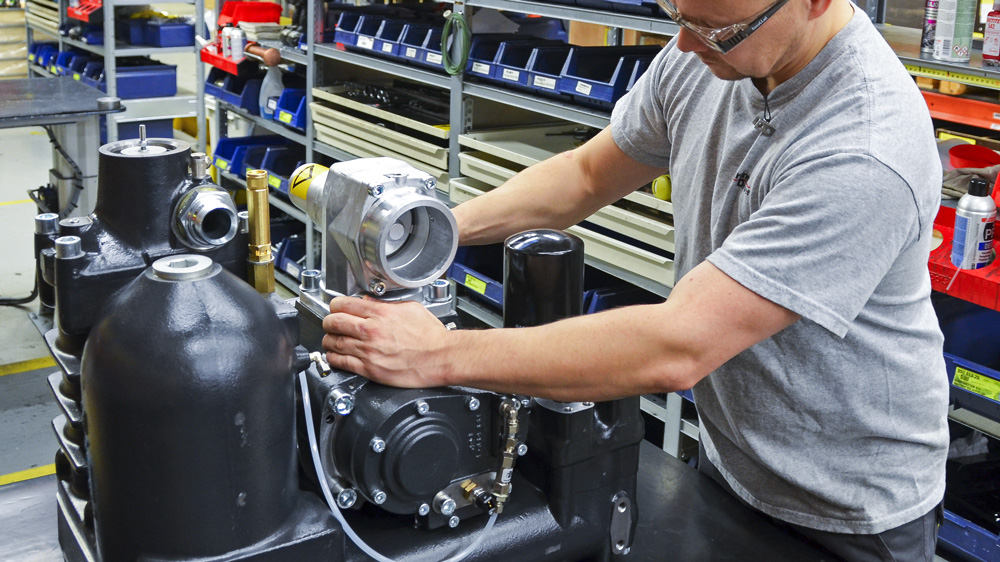

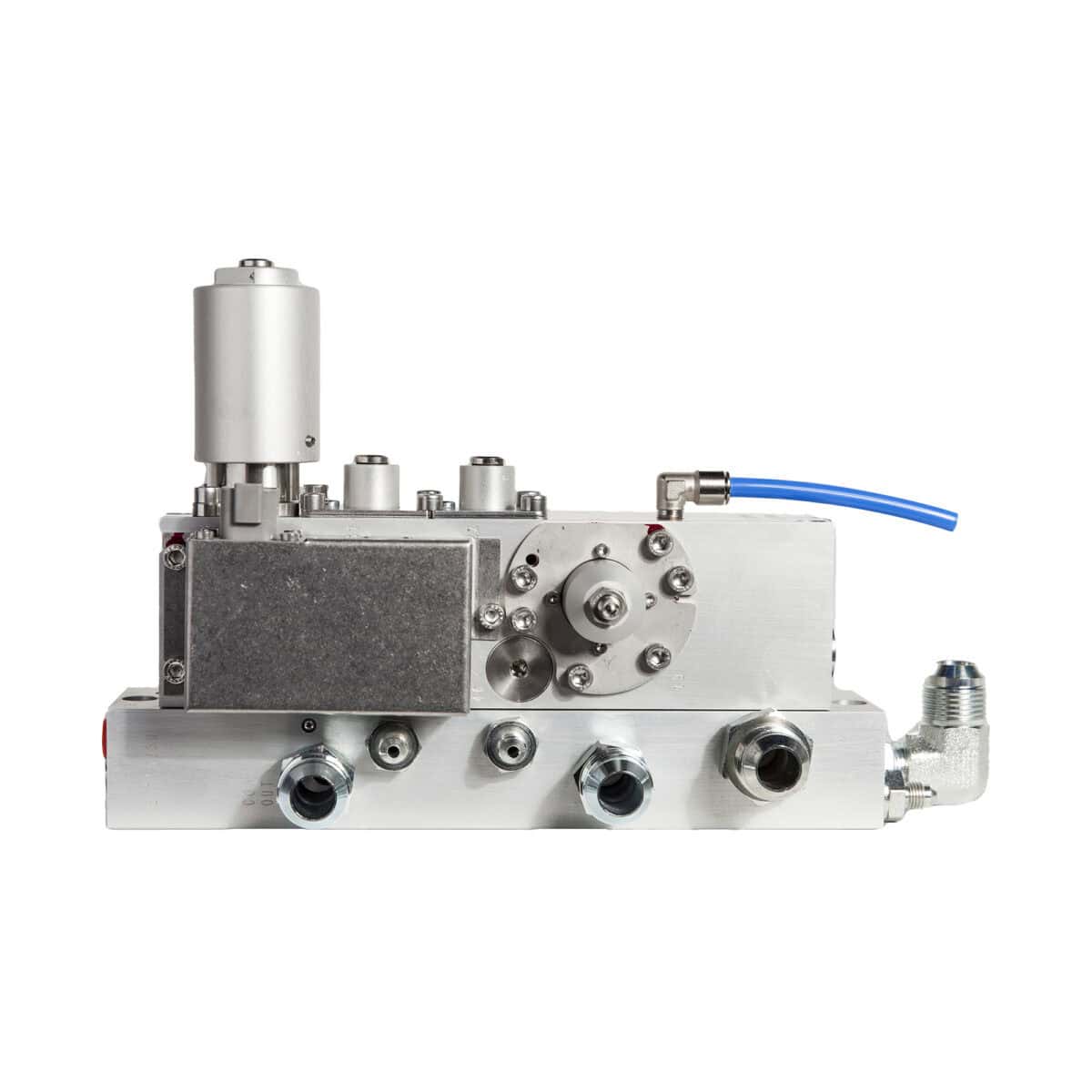

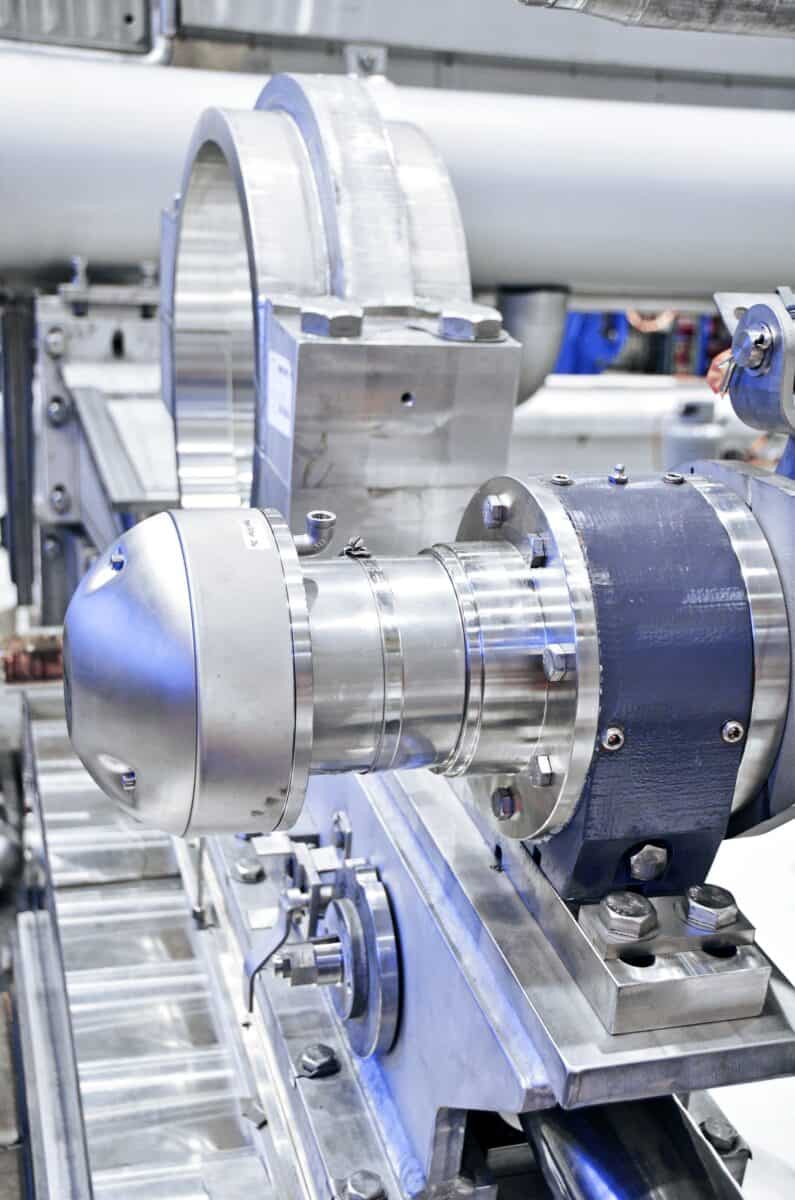

Tailored products

Each of our successful processes stands on Pimatic’s legendary ingenuity, creativity and problem-solving mindset. Our innovative and customer-driven product development is at the core of our expertise. As experts, we get excited when challenged to find an optimal solution to a unique problem. We’re here to help you succeed.