Tailored products

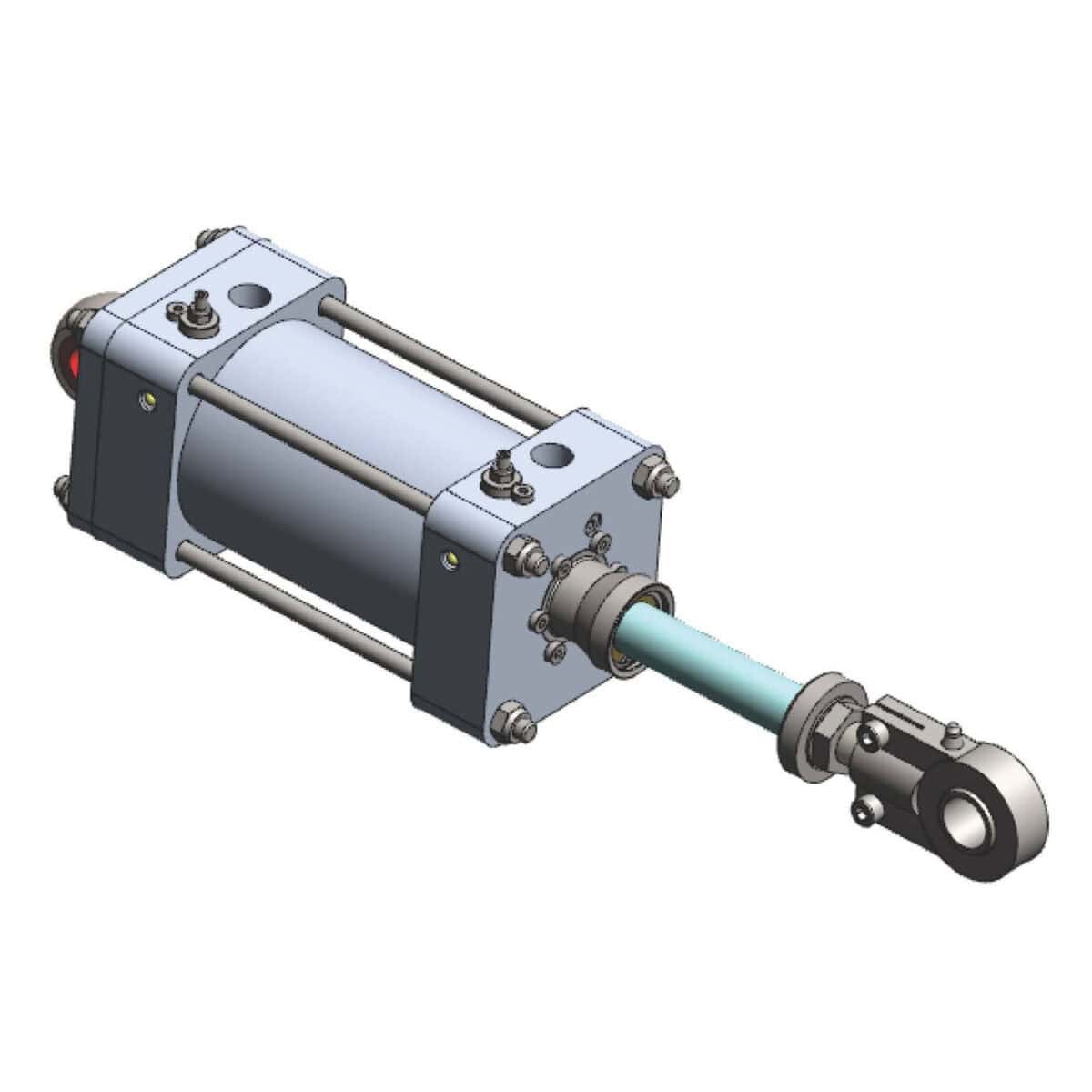

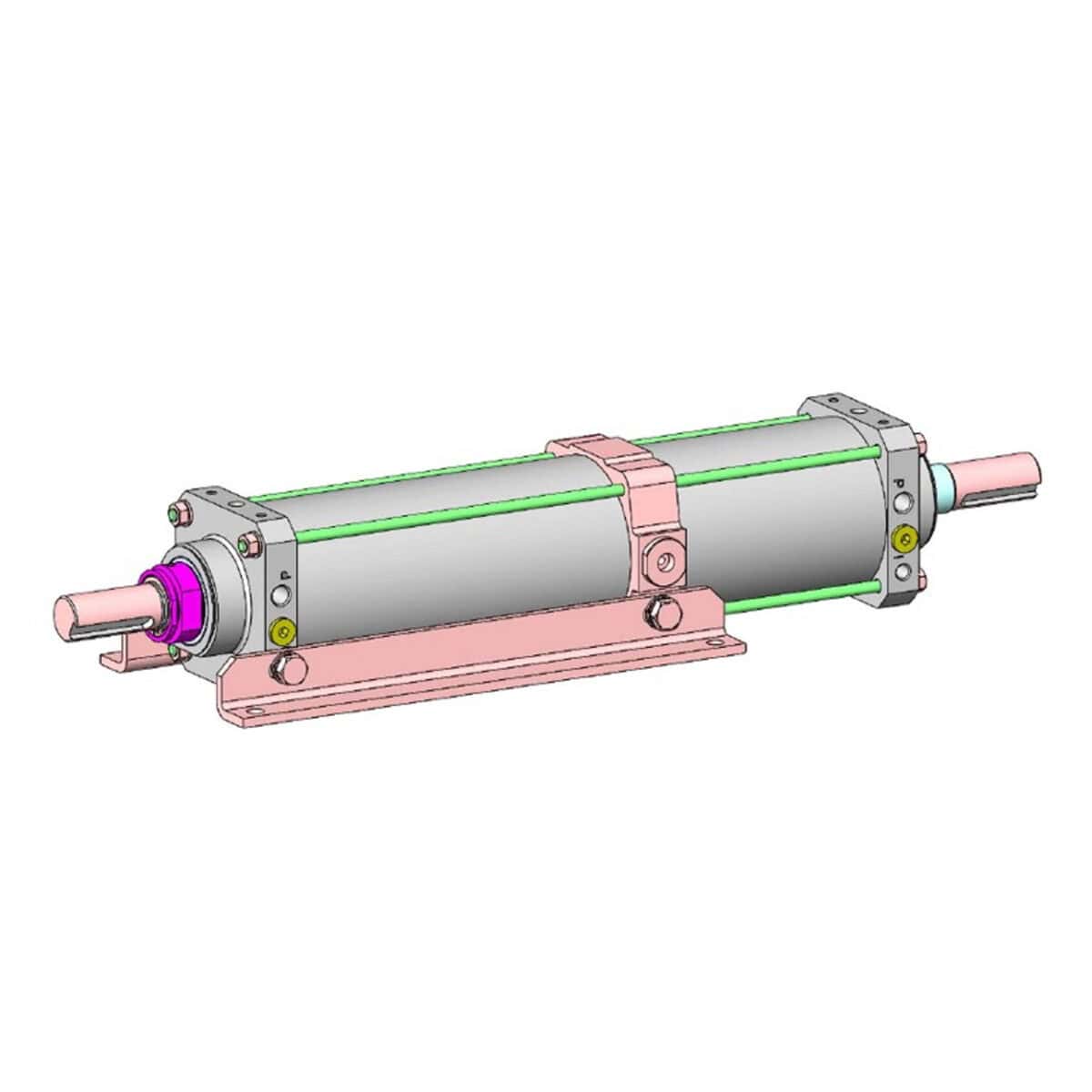

Tailored cylinders

We design customized cylinder solutions for our customers, where only imagination sets the limits. As we like to say — where others’ expertise ends, ours is just getting started.

Tailored products

We design customized cylinder solutions for our customers, where only imagination sets the limits. As we like to say — where others’ expertise ends, ours is just getting started.

Our trimmer cylinder comes with many benefits compared to traditional cylinders, including:

Case study: An actuator for lowering upper blades of a winder with integrated manual override valves.

Thrust force:min. 1,3 kN – spring force 290 – 475 N

Ominaisuudet:

The oscillating cylinder PPO is designed for applications requiring continuous back-and-forth motion. The PPO is made from materials that withstand the demanding conditions present in paper machines. Oil mist lubrication is strictly prohibited, or an oil removal filter must be used.

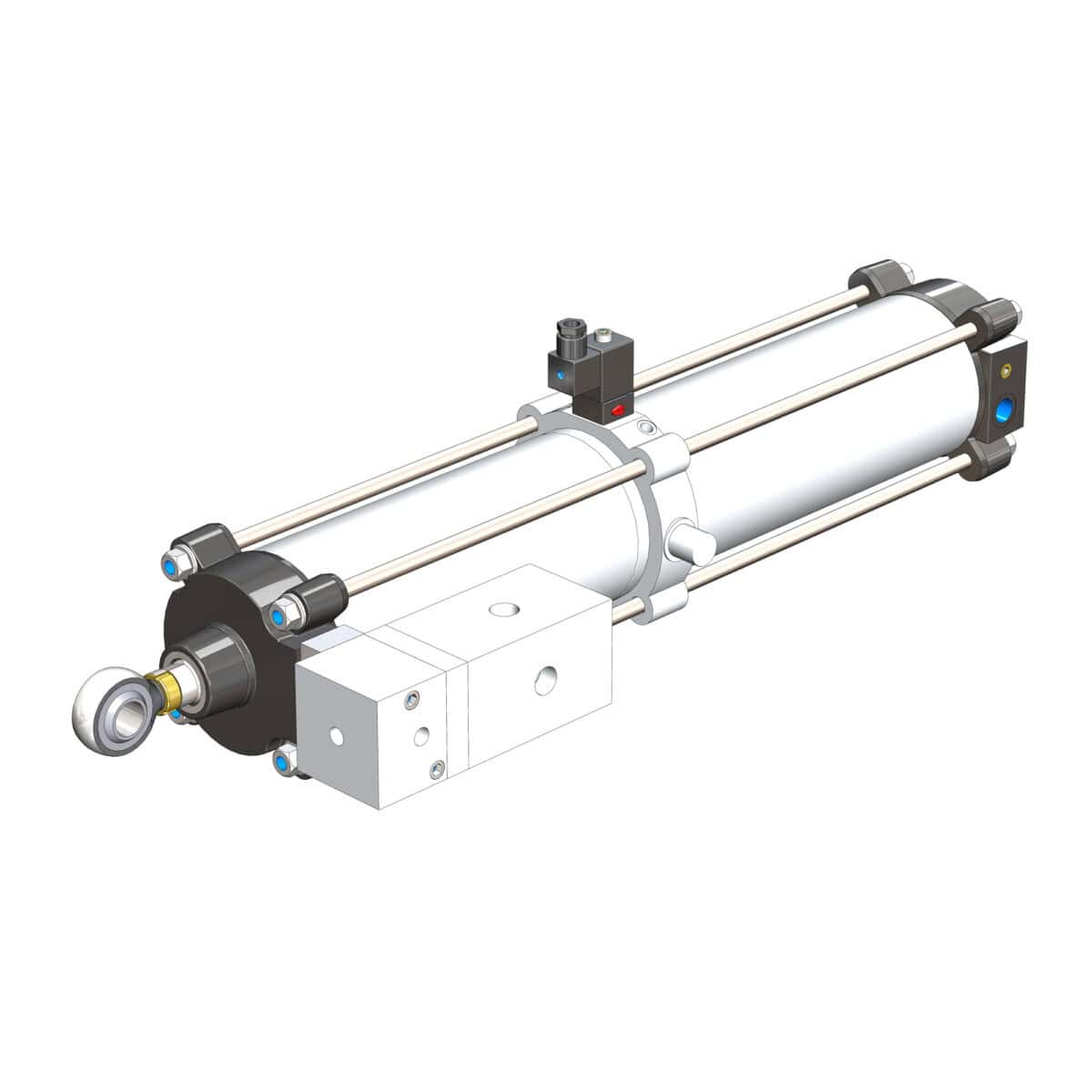

High speed cylinder with integrated release valve and adjustable end cushioning.

Benefits:

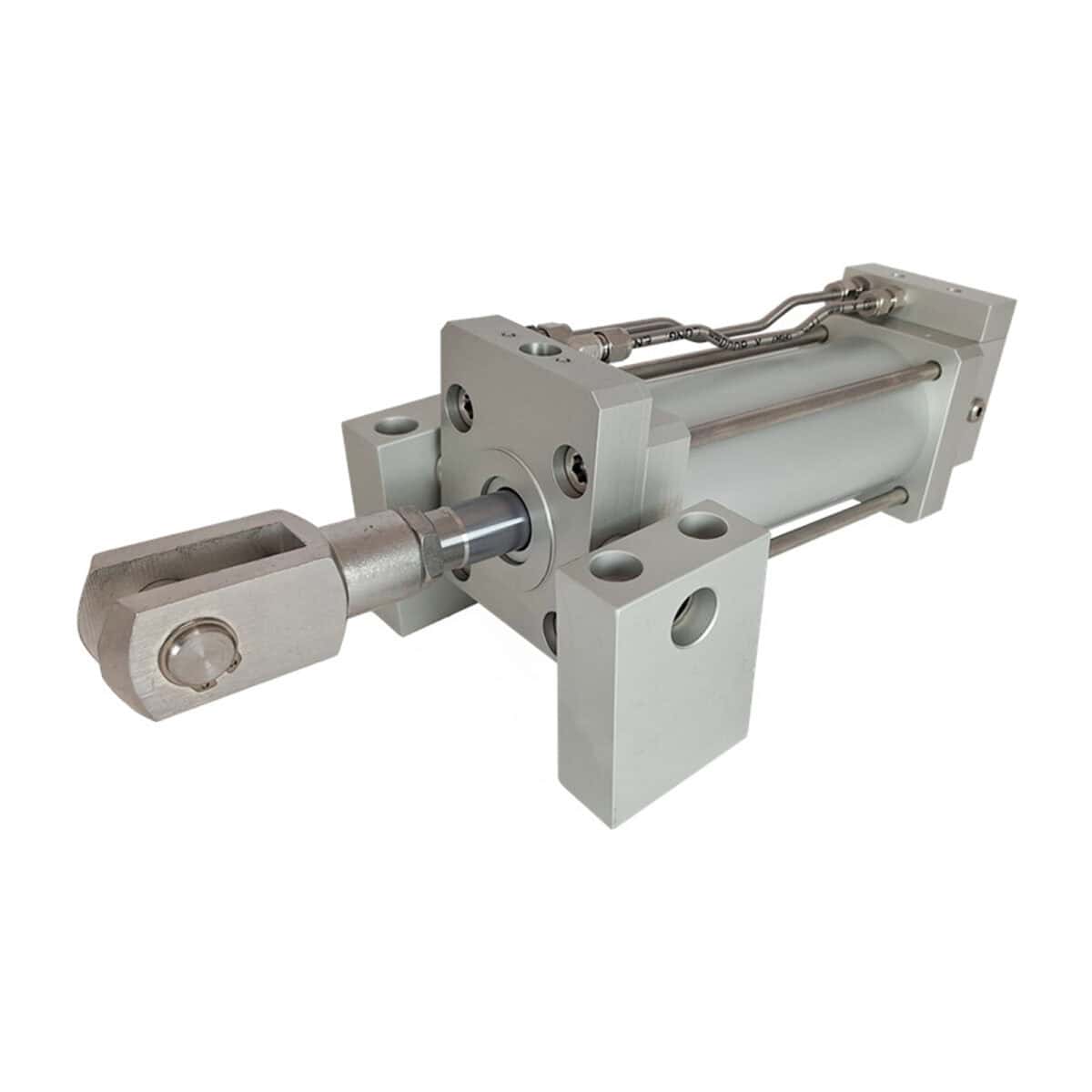

A pneumatic cylinder equipped with hydraulic shock absorbing function at the front end.

Benefits:

Cases — Pensi Rescue

Pensi is a Finnish company specialized to meet the challenges of patient transportation. Based on specialized techology, Pensi enables the safe and ergonomic transfer of patients also in the stairways.